In a context where reducing CO₂ emissions and improving energy efficiency are at the forefront of industrial concerns, FIB GROUP is innovating with the development of full electrical heating immersion heaters.

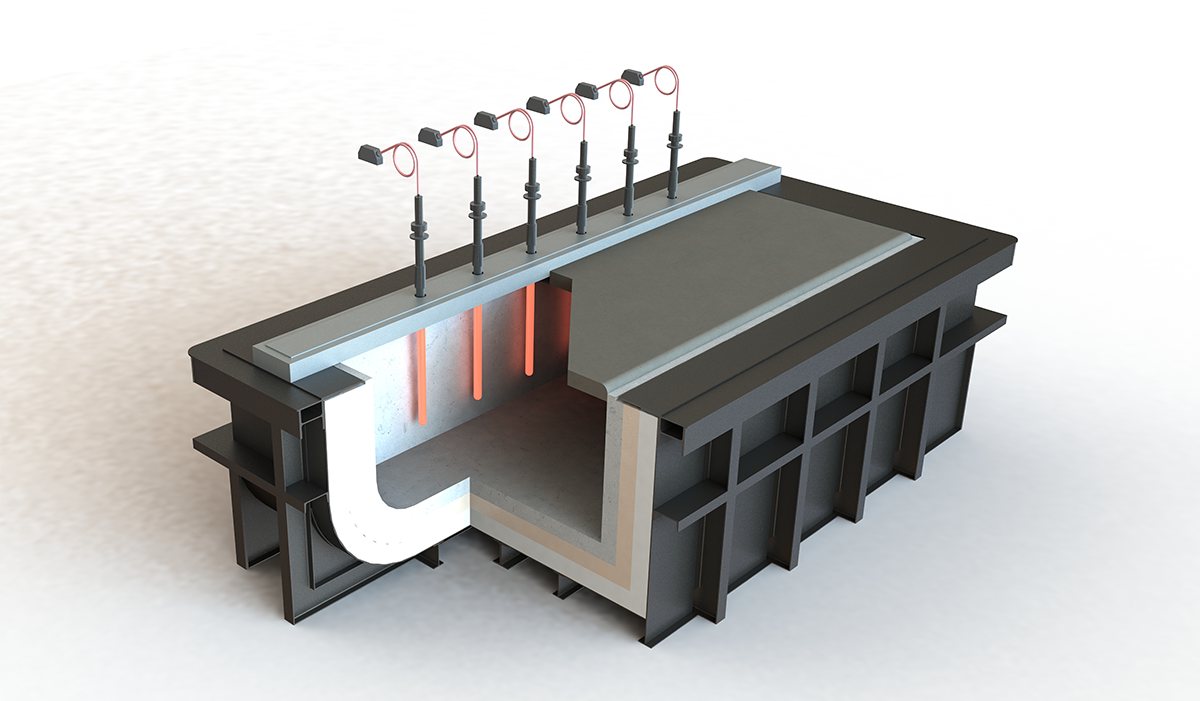

FIB GROUP’s electrical immersion heater offers higher efficiency than even the most advanced combustion systems. “Their direct immersion and the advantage of the electrical resistance allow for optimal energy transfer, reducing losses and increasing overall efficiency,” explains Paul-Gaëtan Bareel, Commercial Director.

Light and robust, the electrical immersion heater can work at high temperature and is very quickly installed, offering many advantages. This equipment can be used as main heating system or as emergency backup heating system. Indeed, galvanizing baths must maintain a constant temperature to prevent the zinc from solidifying, which could damage the installation and lead to significant time and energy losses. The electrical immersion heater solution ensures to keep your zinc liquid.

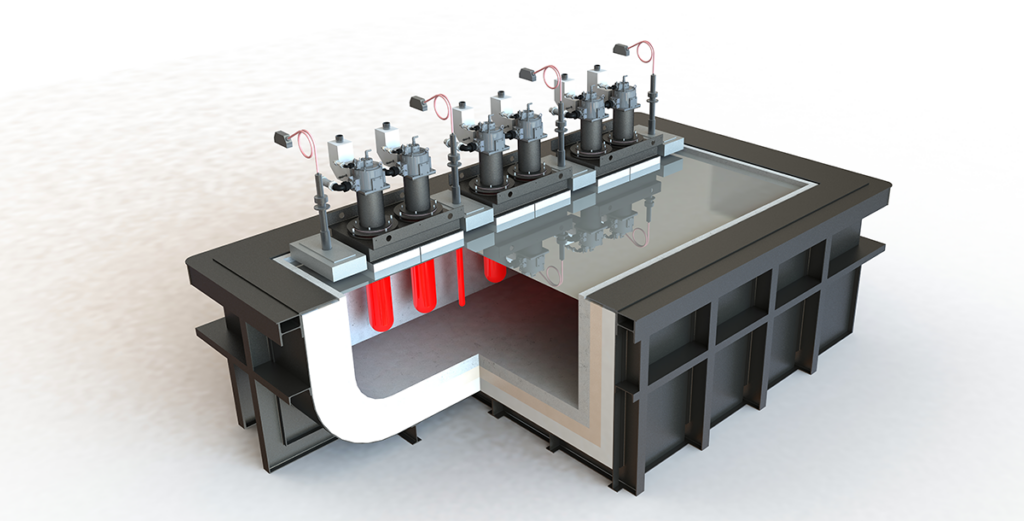

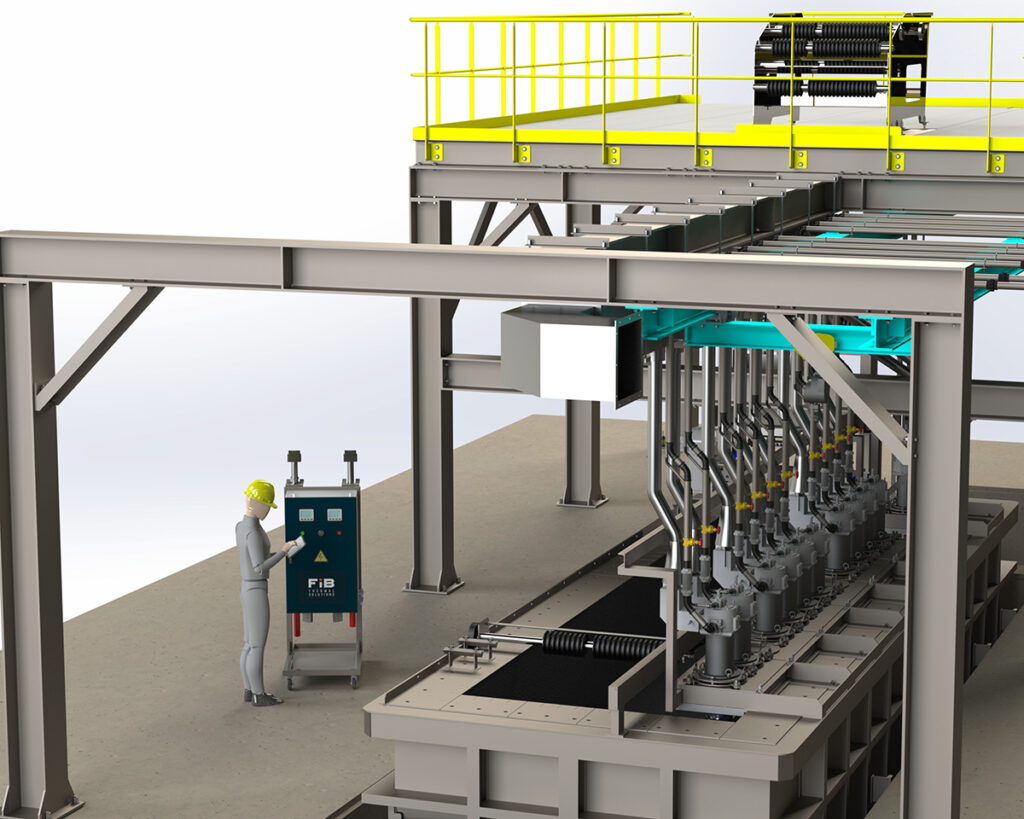

At sight of the energy transition, this innovation can be also used as hybrid solution combining gas burners with electric heating elements immersed in zinc. Already successfully implemented in Spain and Brazil, this solution offers major environmental and economic benefits: a significant reduction in CO₂ emissions, lower production costs, and increased capacity to handle demand peaks.

In case of gas or electricity shortage, our hybrid system keeps your zinc liquid, which prevent any damages to the installation and eliminate significant time and energy losses. Your production is therefore guaranteed.

High flexibility with our hybrid system

One of the key advantages of this new system is its operational flexibility. Companies can prioritize gas or electricity depending on real-time conditions. When equipped with solar panels, businesses can maximize the use of renewable energy during the day while switching to gas when electricity is expensive or unavailable. “Clients can also combine gas and electricity to manage production peaks by utilizing all available power.”

Metallic or ceramic galvanizing furnaces

Whether the tank is metallic or ceramic, with immersion burners or a top heating cover, FIB GROUP’s hybrid technology adapts to all existing configurations. “The compact installation of electric heating elements allows for easy integration without requiring major modifications. The lightweight design of this equipment also simplifies handling.” Since 2023, FIB GROUP has installed six hybrid systems in Spain, ten in Brazil and three in Italy. “New orders are in progress for other regions. Our clients’ feedback confirms the reliability and efficiency of this technology,” concludes the Commercial Director.

Why wait? Order FIB GROUP’s hybrid solution today!

Don’t let fluctuating gas and electricity prices or environmental challenges slow down your production. Choose performance, flexibility, and sustainability with FIB GROUP. Contact us today to see how we can tailor this solution to your facilities. info@fib-group.com