Specializing in the design and manufacturing of industrial furnaces, FIB GROUP integrates cutting-edge combustion systems. Pre-mixing technology is a major advantage for the wire drawing and glass industries.

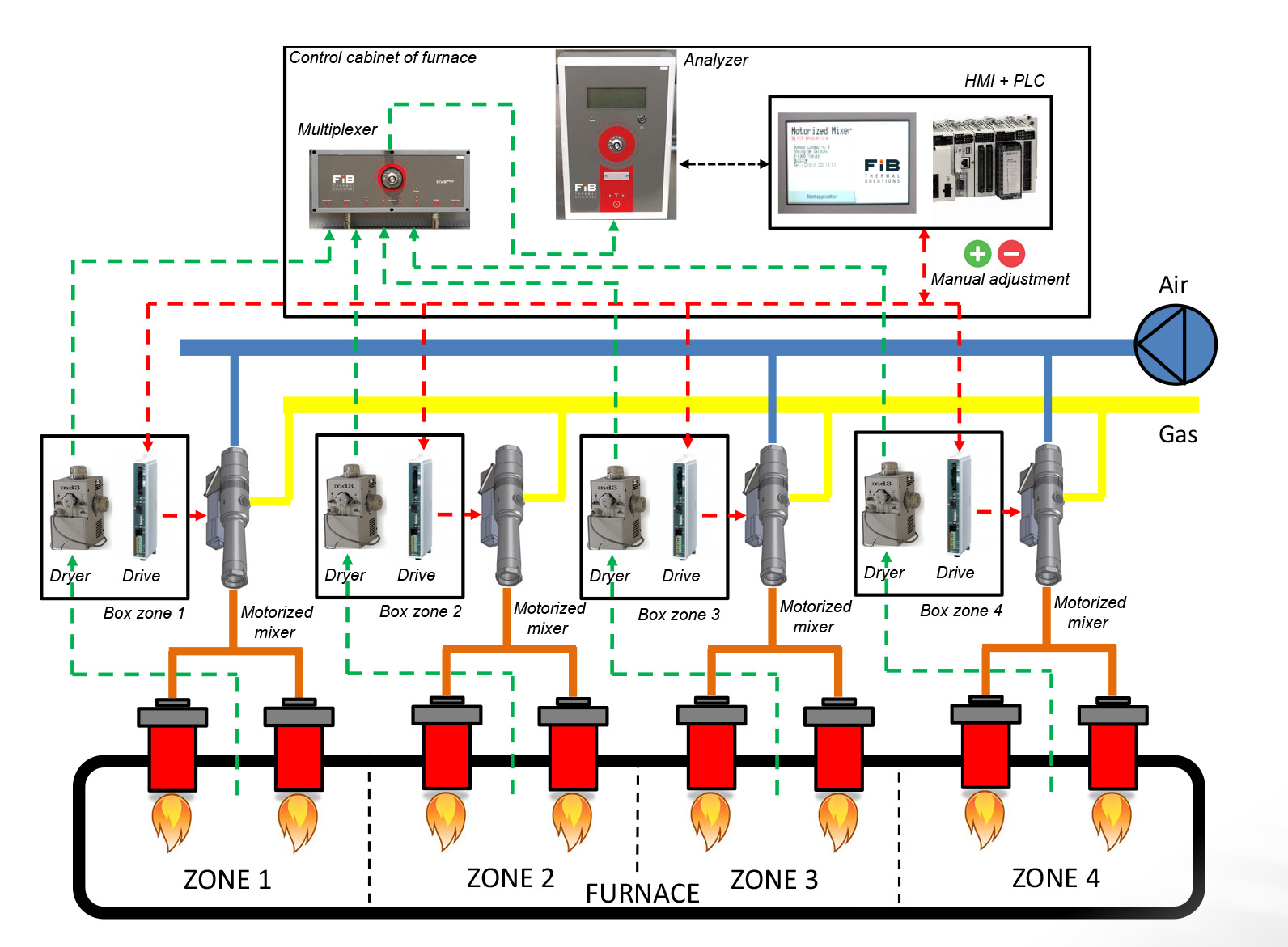

In this process, air and gas are mixed before being supplied to the burners. All burners are fed by the same pre-mix and the same mixer, ensuring a homogeneous and perfectly controlled supply across an entire zone, as well as precise regulation of the furnace atmosphere. “Our internally designed mixers allow for simple manual optimization of the air/gas ratio,” explains Erdinç Sezgin, Technical Director of FIB GROUP. “Depending on the process requirements, the atmosphere can be adjusted to a reducing, stoichiometric, or oxidizing mode.” This flexibility is crucial in energy intensive industries such as steel wire processing and glass manufacturing, where product quality directly depends on precise atmospheric control. “In the glass industry, where the color shades of bottles are influenced by the furnace atmosphere, the consistency of the pre-mix is a major advantage.”

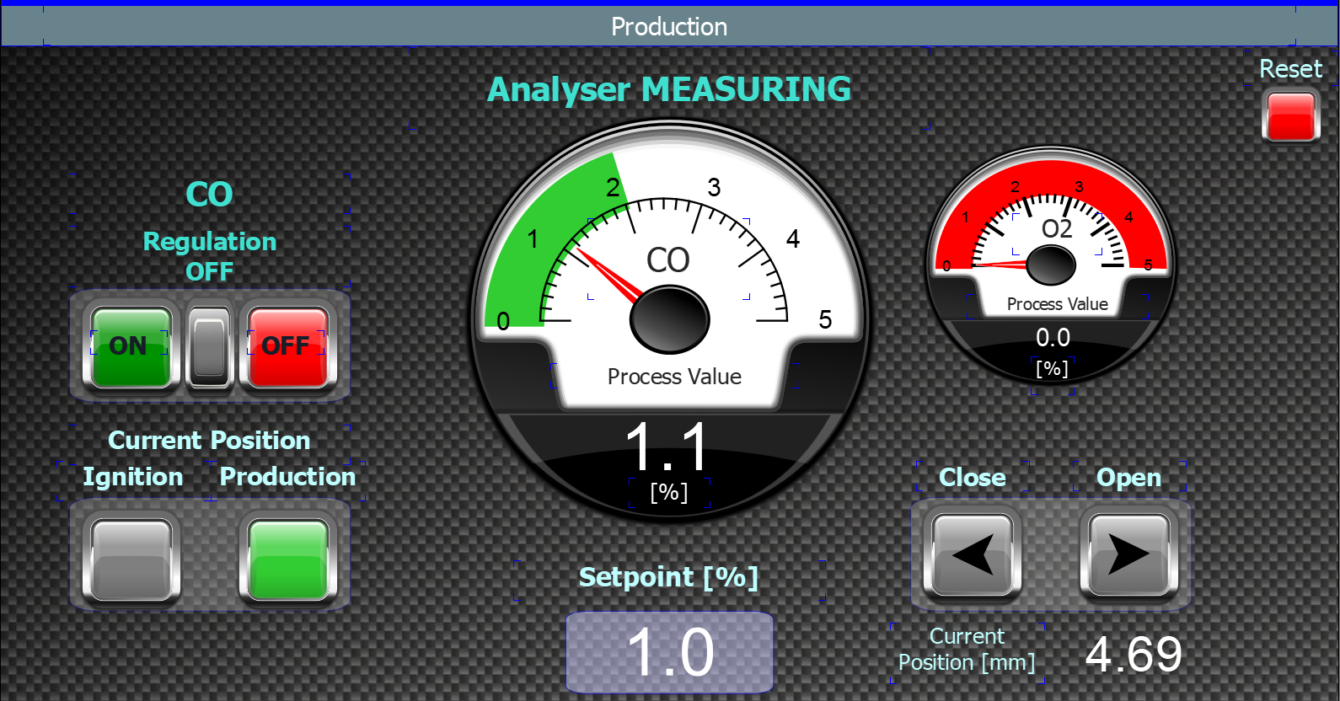

To further optimize precise combustion control, FIB GROUP has developed a continuous atmosphere analysis system. Instead of manual adjustments, an electric actuator adjusts the air/gas ratio.

“An atmosphere analyzer continuously measures key parameters,” continues the Technical Director. This system operates sequentially, sampling and measuring the atmosphere in one zone before moving to the next. It can be equipped with oxygen, hydrogen, and carbon monoxide measurement cells. “Thanks to the multiplexer, a single analyzer can control up to four combustion zones.”

Numerous benefits

The multiplexer saves time and labor. “No more frequent manual adjustments are needed,” notes the Technical Director. It also improves product quality, as a stable atmosphere ensures a stable product. Moreover, better combustion control reduces gas consumption, and the system compensates for fluctuations in gas composition, particularly when hydrogen is injected.

Automated and responsive monitoring

This system defines optimal thresholds for each furnace zone, optimizing everything in real time to ensure maximum efficiency. If limits are exceeded, an alarm is triggered, allowing the operator to instantly adjust the air-gas ratio via an intuitive interface. Additionally, precise mixer positions can be saved, making it easier to quickly return to an optimal setting based on the product being processed.

A profitable and sustainable investment

Choosing FIB GROUP’s pre-mixing and continuous analysis technology means opting for precise furnace atmosphere control, ensuring optimal production quality and significant cost savings.

Want to learn more about our combustion solutions tailored to your industry?

Contact us: info@fib-group.com